Graso creates and runs palletizing and packaging processes based on Kawasaki robots.

Why is it worth it?

Packing and palletizing (or depalletizing) are tasks that burden employees a lot. Therefore, it is often the efficiency of the end of the production line that determines the production capacity of the entire plant. The solution is to robotic palletizing and packaging, which guarantees appropriate efficiency of packing and shipping products, regardless of the staffing situation. This solution therefore opens up the possibility to produce more and faster while reducing waste.

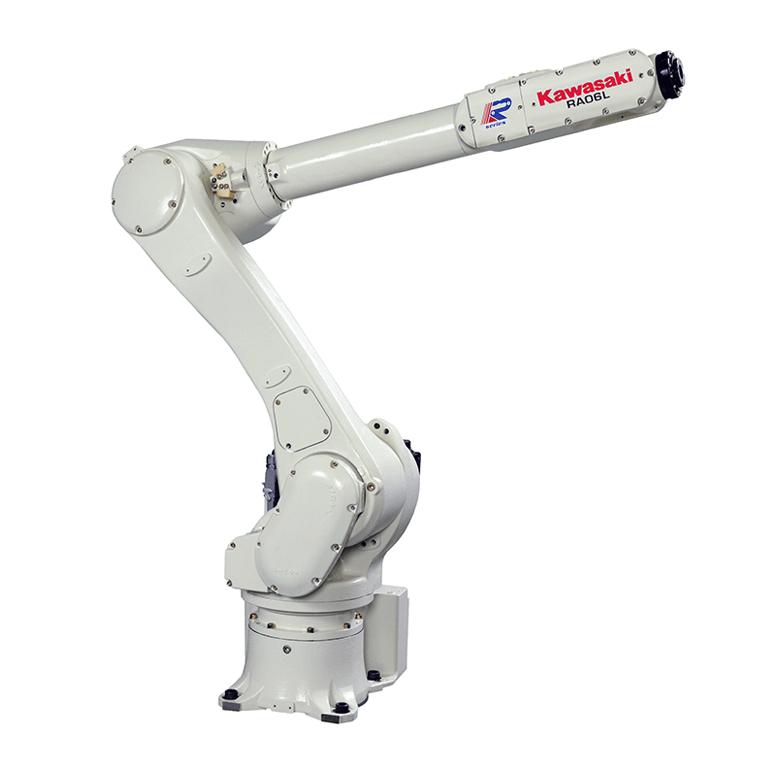

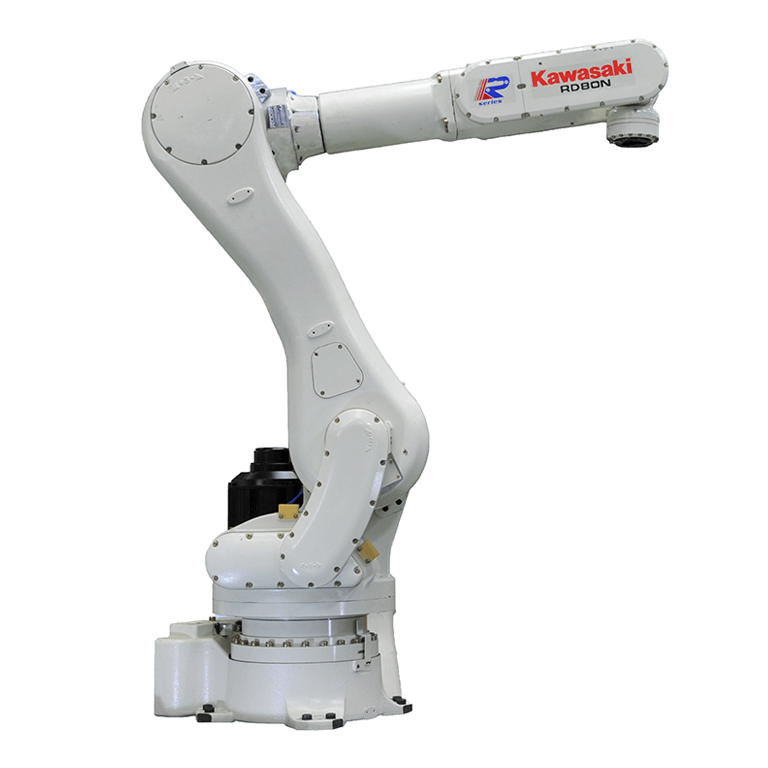

Examples of industrial robots

Benefits

| Before implementation | After deployment | |

|---|---|---|

| Current status | Operational benefits | Economic benefits |

|

|

|

Any questions?

If you are interested in the offer, please contact us. We will answer any questions you may have.

+48(58) 562-56-61